With Tecthan it’s possible!

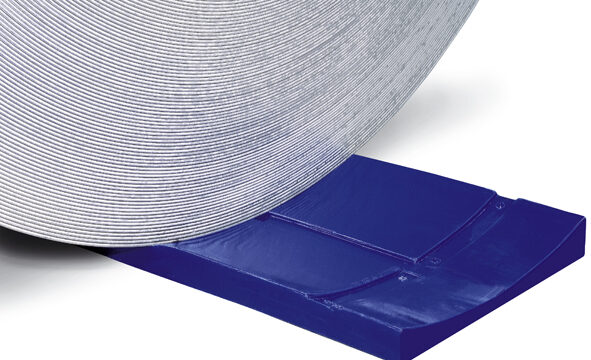

In the production and processing of food, things can get a little rough. At the same time, of components with food contact, high requirements must be met. Only materials that ensure that contamination of food with harmful substances is excluded may be used.

Finally, for food processing applications, you can use the wonderful properties (abrasion resistance, cut resistance, elasticity) of polyurethane for machine components. These properties make polyurethane (PUR) significantly different from plastics such as PP or PE, which are often used in the food sector. Special Tecthan formulations comply with EU Regulation 10/2011 as well as 1935/2004 or we can issue an FDA positive declaration.

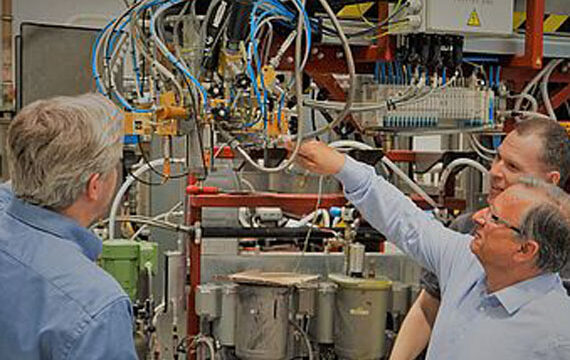

With polyurethane components you can implement problem solutions such as wear protection, vibration damping, sealing and noise reduction. We have already successfully implemented some exciting projects (seals, hoppers, wear plates, …). Perhaps polyurethane can also solve one of your problems…

If you have any questions about specific applications or further material data, please contact our sales team:

Inquiries to: ela-thl-anfragen@polytec-industrial.com

Outlook:

To date, processing of polyurethane (PUR) in the food sector has been limited to casting components. Initial trials with a sprayable material make us confident that we will soon be able to offer our customers a perfect solution in this area as well.