Polyurethane is a liquid multi-component plastic that reacts with one another by bringing the components together. This can essentially be distinguished from the injection molded part because it is not granulate and therefore cannot be reprocessed.Polyurethane is mainly used as a wear plastic in a wide variety of industries.

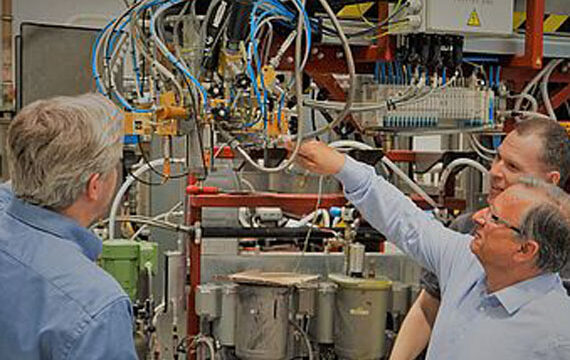

In practice, the casting process is carried out using the company’s own Polytec EMC systems. The individual components are mixed in the so-called mixing head. Components are essentially prepolymer, crosslinker and color. The mixed components are then poured into a preheated mold. After a certain time the component can then be shaped. Basically, it is also possible to cast steel, aluminum or other materials.Furthermore, different hardnesses can be combined, for example to combine the property of wear protection with a damping effect of a soft polyurethane. This soft cushioning layer can either be designed as a normally cast polyurethane or as a polyurethane foam.

All in all, polyurethane is a highly wear-resistant material that can be cast in various hardnesses, variants and properties. Through our in-house laboratory, we can individually address your properties. So don’t be afraid to contact us and maybe the next development will be based on your project.